Corporate InformationCompany

Overview of Azuma and introduction of our history and activities

-

Corporate Overview

-

Group Companies

-

CSR

-

History

Corporate Overview

Azuma Co., Ltd.

-

Azuma Co., Ltd. Headquarters

-

Headquarter Entrance

-

Tokyo Business Office

-

Tokyo Business Office Entrance

| Location |

|

|---|---|

| Company Representative | President & CEO Katsuya Yamazaki |

| Capital | 98 million yen |

| Foundation Date | May 1, 1962 |

| Employees | 150 employees as of April 1, 2025 |

| Main Banks | Chiba Bank Goi Branch, Chiba Shinkin Bank Goi Branch, Japan Finance Corporation Chiba Branch, Chiba Kogyo Bank Goi Branch |

Group Companies

AZmax Co., Ltd.

| Capital | 85 million yen |

|---|---|

| Location |

|

| CEO | Katsuya Yamazaki |

| Foundation Date | April 1, 1995 |

| Business field | Sales of silicon, organic metal, fluorine compounds, kits for food sanitation inspection/environment sanitation inspection |

| Employees | 17 employees, as of March 1, 2020 |

Azuma Logistics and Warehousing Co., Ltd.

| Capital | 85 million yen |

|---|---|

| Location | 1-6-13 Tamasaki-Nishi, Ichihara City, Chiba 290-0044 TEL: +81-436-20-7055 FAX: +81-436-20-7056 |

| CEO | Katsuya Yamazaki |

| Foundation Date | September 1, 1999 |

| Business field | Logistics business for chemical products |

| Employees | 15 employees as of April 1, 2025 |

Goi Bussan Co., Ltd.

| Capital | 10 million yen |

|---|---|

| Location | 1-4-12 Tamasaki-Nishi, Ichihara City, Chiba 290-0044 TEL: +81-436-21-1931 FAX: +81-436-21-1915 |

| CEO | Katsuya Yamazaki |

| Foundation Date | July 1, 1961 |

| Business field | Designated passenger vehicle transportation, worker dispatching, other |

| Full Employees | 35 employees as of April 1, 2025 |

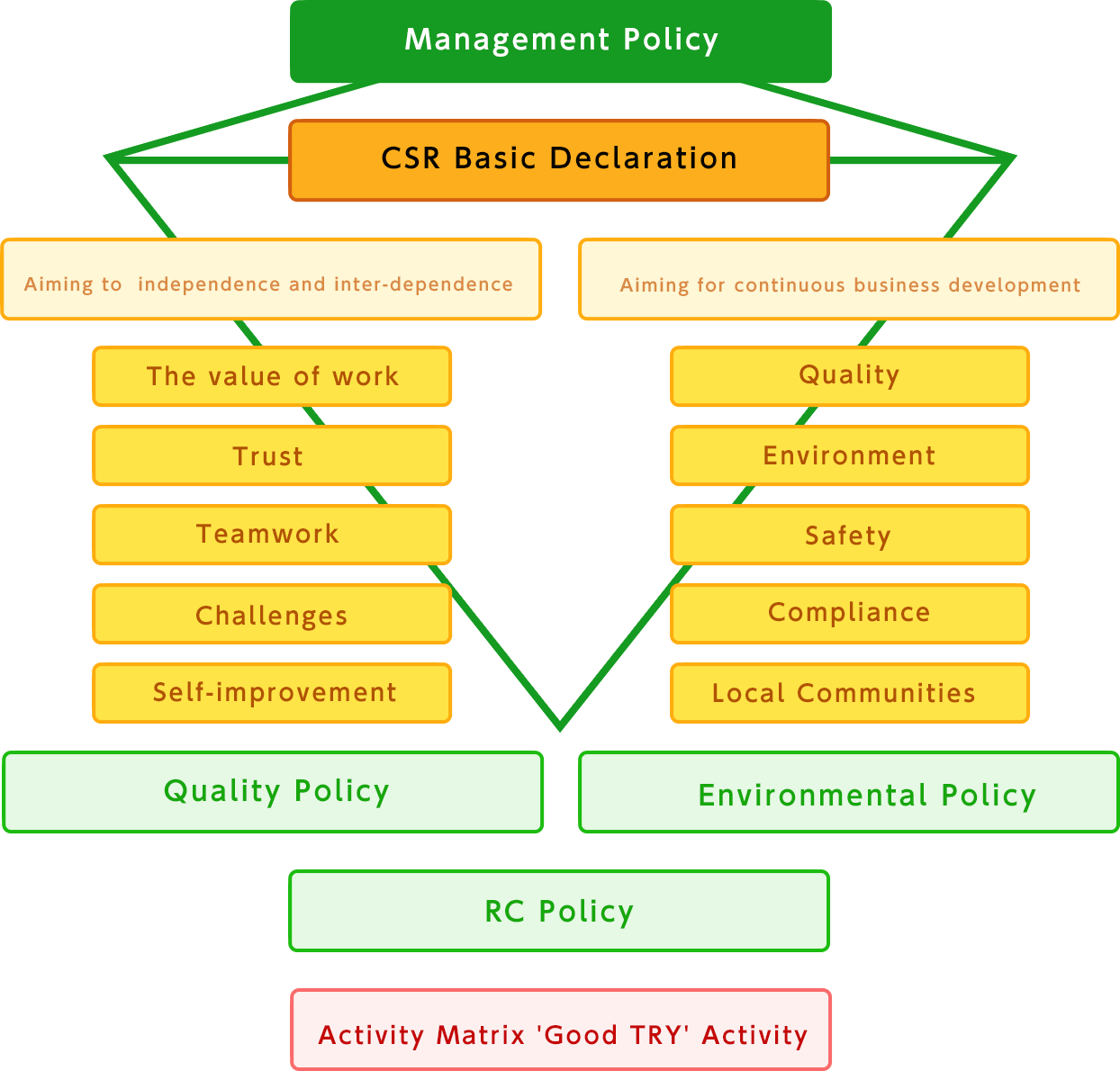

CSR

Business Vision

Our Mission

Azuma Group’s sustainable growth depends on our ability to earn our customers’ trust by responding to their ever-changing needs swiftly and in the most suitable manner. This is how we aim to contribute to the development of global industry and a sustainable society.

Our Core Values

Azuma Group places the highest importance on the potential, growth, and well-being of each employee of our organization. Employees are encouraged to challenge themselves and supported in their growth toward goals and self-realization.

The Spirit of Our Business

- 1) People-centered management

- 2) Carefully attention to the demands of customers

- 3) The spirit of collaboration and mutual benefit to create win-win for all parties involved

- 4) Always prioritize quality, safety, and the environment, to contribute to the development of a sustainable society.

CSR Declaration

~Toward independence and synergy~

We believe in people-centered management.

- Independence:

- Rooted in the best traditions and an international perspective, Azuma Group aims to be the first, striving with continuous effort for originality. We take our responsibilities seriously without relying on others.

- Solidarity:

- We believe in sharing our wisdom toward achieving a common goal. We value harmony, peace, and transparency.

- Thus:

- We believe that by connecting diverse and self-reliant individuals, we can develop toward a brighter future.

The Satisfaction of a Job Well Done

We believe in creating a corporate culture that’s worth joining. How do you create a culture like this? Be respecting each person’s individual merits and abilities, encouraging each other toward their desired achievements, and celebrating each success together along the way.

Mutual Trust

We work to build a trusting and respectful relationship among all parties within our organization.

Teamwork

We believe that a flexible mindset and proactive information sharing can produce a multiplier effect on creativity and focus. Put all these elements together and you have a strong team that gets results.

Facing Challenges

We encourage our people to face challenges head-on and overcome them through innovation and timely response.

Continuous Self-improvement

We recognize our own roles, aiming for independence gained through research, training and learning the knowledge and skills necessary for ourselves and the company.

~Toward sustainable development~

A High Standard of Quality

We aim to continuously raise our customers’ level of satisfaction through a thorough understanding of their needs and constantly improving our technologies and facilities to produce the highest-quality products possible.

Environmental Protection

We consider the coexistence of the chemical industry and natural environment an issue of extreme importance. We will utilize all resources available to protect the environment and prevent pollution.

Concern for Safety

We make being accident free and disaster free our main priority, taking every necessary measure to ensure safety and hygiene of the working environment, security and disaster prevention, and the safe handling of chemicals.

Regulatory Compliance

We believe in open, fair, and free competition and ethical trade practices. We stay current on all relevant laws, agreements, and regulations to ensure total compliance.

Community Participation

We recognize ourselves as a member of the community. We actively participate in regional activities, ensuring the peace and safety of the civic and community life. Information about our activities is open to the public.

Our Quality Policy

- 1) Prioritize our customers’ needs above all else.

- 2) Promote the establishment of an effective management system aiming to deliver the products and services our customers expect.

- 3) Creatively pool our wisdom and utilize the most suitable technologies.

- 4) Maintain high value on communication with our customers, prioritizing promptness and courtesy.

- 5) Advance effective continuous improvement through full participation of all members to maintain trust into the future.

Environmental Policy

Basic principles

‘Our group recognizes its responsibility to address environmental issues and contribute to realizing a prosperous society and environment.’

Guidelines for Action

- 1) Comply with environmental laws and requirements from third-parties to which our Group agrees.

- 2) Ensure that all employees are aware of our environmental policy and strive to provide environmental management education and awareness.

- 3) Promote resource and energy conservation across all business activities.

RC (Responsible Care) Policy

Basic principle

Implementation of the 5S methodology

Slogan

‘Know and Follow the Basic Rules: We Can Achieve Zero Accidents If We Work Together.’

Our Goals

‘Achieve 5 zeros’ – Zero Disasters / Zero Trouble / Zero Complaints / Zero Emissions / Zero Illnesses

Information Security Policy

Azuma Group will protect the information assets entrusted to us by our customers and our Group’s own information assets from threats such as accidents, disasters, and criminal activity. To justify the trust placed in us by our customers and society, we will implement information security measures company-wide based on the following policies.

1. Management Responsibility

Azuma Group strives to improve and enhance information security in an organized, continuous, and management-led management.

2. Internal Regulatory Structure

Azuma Group has established an organization dedicated to maintaining and improving information security and defines information security measures as formal internal regulations.

3. Employee Commitment

Our employees acquire the knowledge and skills necessary for information security and guarantee their commitment to our information security efforts.

4. Compliance with Laws, Regulations, and Contractual Requirements

Azuma Group complies with all laws, regulations, standards, and contractual obligations related to information security, while also meeting customer expectations.

5. Response to Violations and Incidents

Azuma Group will appropriately address any violations of laws or contracts, or incidents related to information security, and strive to prevent recurrence.

Good TRY Activity

At Azuma, we refer to activities that contribute to health, safety, and quality as “Good TRY Activities.” These include activities such as additional education and training, near-miss reporting, hazard prediction, and improvement proposals. Points are awarded for each activity type, and department-level recognition is given every six months.

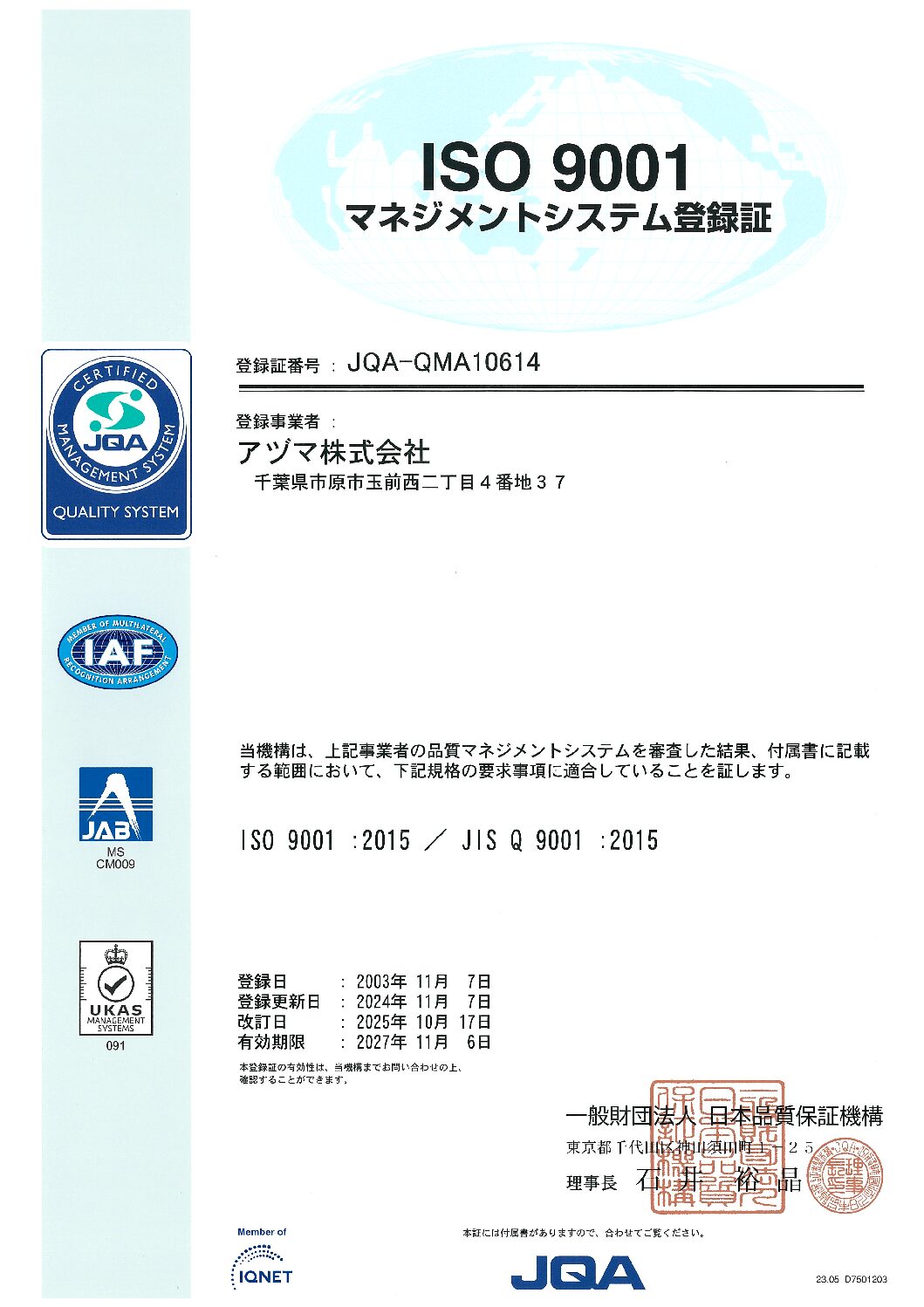

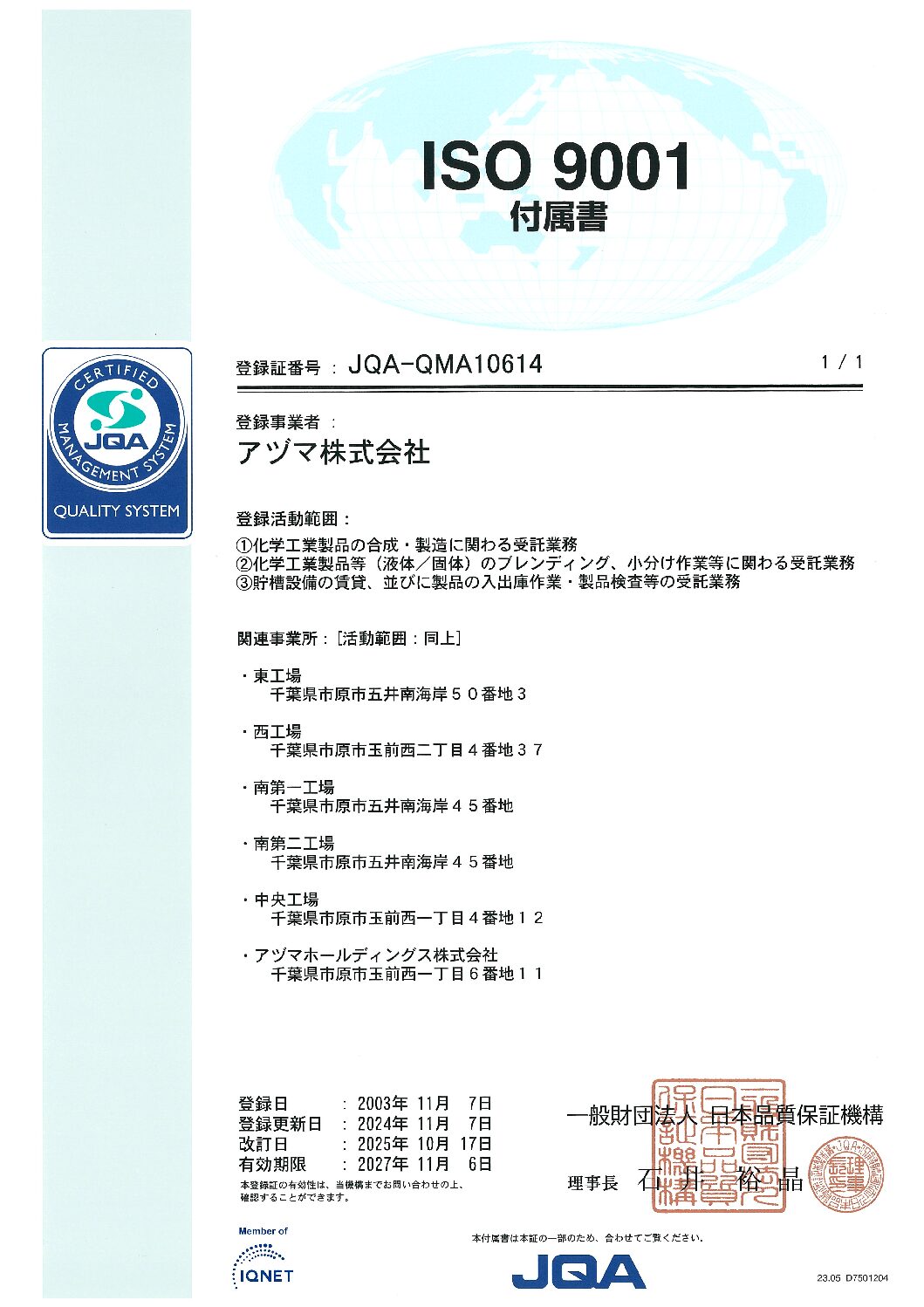

ISO 9001 Certification

Azuma Co., Ltd. has obtained the international standard certification of ISO9001:2015 for quality management.

History

| 1962 | May – Established ‘Azuma Trading Ltd.’, which dealt in sales and delivery of various commodities to the Keiyo industrial area |

|---|---|

| 1966 | July – Company name changed to ‘Azuma Chemical Engineering Ltd.’ |

| 1968 | May – Built plant in Goi Minami-Kaigan in Ichihara City, started acetic acid packing and filling. |

| 1973 | August – Received General Regional Motor Truck Transportation certification from Chiba District Land Transport Bureau |

| 1974 | October – Built West Plant at Tamasaki-Nishi in Ichihara City |

| 1979 | September – Changed from ‘Azuma Chemical Engineering Ltd.’ to ‘Azuma Chemical Engineering Co., Ltd.’ |

| 1981 | April – Built cleaning facility for flexible containers in West Plant, operation started. |

| 1986 | May – Company name changed from ‘Azuma Chemical Engineering Co., Ltd.’ to ‘Azuma Co., Ltd.’ |

| 1987 | July – Headquarters built and moved to West Plant |

| 1989 | February – Received certification to start warehouse business from Kanto District Transport Bureau |

| 1990 | March – Built washing facility for flexible containers at Tamasaki-Nishi in Ichihara City, operation started |

| 1991 | February – Built Kisaragi Office Research Building at Shiohama in Kisaragi City, operation started |

| 1995 | April – Advanced Products Division became independent, established AzMax Co., Ltd. |

| 1996 | August – New office building for the First Chemicals Division (East Plant) |

| 1998 | March – Flexible Container Division became independent and Azuma Flexible Container Maintenance Co., Ltd. established. |

| March – Tokyo Business Office opened | |

| 1999 | March – The First and Second Chemical Divisions merged into Chemical Division |

| September – Freight Division/Container Division/Warehouse Division became independent, Azuma Land Transport & Warehouse Co., Ltd. established | |

| 2000 | March – Obtained exclusive industrial land at Goi Minami-Kaigan in Ichihara City for South Pactory for Chemical Division |

| 2003 | June – Office building in South Plant completed |

| July – Central Plant for Chemical Division was built at Tamasaki-Nishi, Ichihara City | |

| November Chemical Division registered certification for ISO9001 | |

| 2004 | March – First phase of South Plant completed |

| 2006 | April – Renewal of Central Plant completed. Measuring and blending business consolidated |

| April – Experiment building of AzMax Co., Ltd. completed, laboratory synthesis moved to West Plant. | |

| May – Second synthesis building in South Plant completed | |

| 2007 | April – Third synthesis building in South Plant completed |

| December – Added dangerous materials handling station and warehouse in Central Plant, consolidated packing business | |

| 2008 | January – Fourth synthesis building in South Plant completed |

| March – Office building in Central Plant completed | |

| December – Fifth synthesis building in South Plant completed | |

| 2010 | July – Established lorry filling station in East Plant |

| 2011 | October – Renewal of East Plant completed |

| 2014 | February – Renewal of West Plant completed |

| 2015 | June – West Plant awarded ‘Disaster-Free Category 5 (Gold)’ by Japan Industrial Safety and Health Association |

| July – Awarded ‘Excellent Safety Management Workplace Award’ by General Incorporated Labor Standards Association of Chiba | |

| 2017 | October – Awarded ‘Excellent Safety Management Workplace Award’ by Public Interest Incorporated Federation of Labor Standards Associations of Chiba Prefecture |

| 2019 | May – Awarded ‘Excellent Workplace Award’ by Ichihara City Fire Prevention Safety Association |

| July – Sixth synthesis building in South Plant completed | |

| 2020 | December – Establishment of Azuma Holdings Co., Ltd. |

| 2021 | March – Transition to a holding company structure |

| March – Complete overhaul of the acetic acid filling line at the East Plant | |

| 2023 | March – Completion of the Second Filling Facility (Hazardous Materials Handling Facility) at the East Plant; Completion of the second phase of the East Plant renewal |

| July – Completion of Building C at the Central Plant | |

| December – Completion of Building D | |

| 2024 | September – South Plant Second Control Room Expansion |

| November – Central Plant Building E Completed | |

| December – South Plant Second Office Building Completed | |

| 2025 | March – Group Headquarters Building completed; Azuma Holdings Co., Ltd. and Goi Bussan Co., Ltd. relocated |

| March – South Plant divided into South Plant No. 1 and South Plant No. 2 | |

| March – Azumax Co., Ltd. office relocated to Central Factory premises | |

| March – Central Factory Building F Spring Festival | |

| May – Completion of Dormitory and Employee Club | |

| June – Analytical Testing Laboratory relocated to former Azumax Co., Ltd. office building | |

| July – Completion of the Equipment Management Team Office | |

| September – Integration of the Quality Assurance Office and Analysis and Inspection Office into the Quality Assurance Office | |

| September – Completion of renovation work on the West Plant Office Building | |